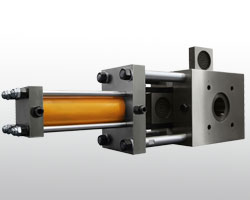

Melt extruder filter screen changer

The screen changer is a manual or automatic switching device that includes one or more filters. It is used to filter out foreign particles and impurities when plasticizing material flow screen. The filter is supported by an alloy porous plate. The porous plate is mounted on a plate or column type carrier, and the carrier can be moved to switch between the working position of a system and the off-line position of the off-line. The exchanger can be installed in any new or existing extruder, melt pump, reactor or other extrusion line. It can be used to filter any type of polymer, rubber or ceramic melt.

It is used for melt filter screen changer in plastics, rubber, chemical fiber and ceramics extrusion production line. These converters - including a low cost manual switch to a highly complex non stop voltage regulator for a extruder with a screw diameter of 35mm to 300mm.

The changer is often used in the following line of production:

1. from plastic resin synthesis reaction device to bulk granular extrusion granulating production line.

2. ceramic extrusion production line.

3. polymer (plastic and rubber) molding production line, including blowing film, casting film, sheet, pipe material, profile, plastic recovery, granulation, wire drawing, underwater particle, color granulation, and extrusion cladding production line.

4. suitable for various granulator, extruder, blow molding machine, drawing machine, sheet extruder, pipe extruder.

Different types of mesh changer are applied to meet different application and process requirements. Manual or low speed netting requires that the production line must have a short time to stop filtering to make changes, while high speed netting and some special structural changer can change the net without stopping the net or slowing the speed of the extrusion. Low cost network changer may produce defective products when changing the network. No stopping device can guarantee the least defective products, but the initial investment is relatively large.