The use of screen changer in the field of chemical fiber recovery

In the process of chemical fiber production, the change of material, equipment, process technology and product variety inevitably lead to the production of waste silk. If not used, on the one hand will form solid waste, or even white garbage; on the other hand, petroleum and other fossil resources are non-renewable, as the downstream petrochemical fiber industry urgently needs to recycle this part of waste. In the process of waste collection, storage and transportation, solid impurities will be mixed. If they are not filtered and reused directly (by adding a mesh screen changer in the chemical fiber recovery process, impurities in the melt can be filtered effectively), which will lead to the next process of recycled materials, such as recycled spinning, injection molding, etc. can not be carried out normally, affecting the final production. Quality of products.

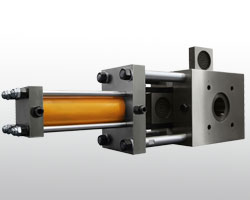

Zhengzhou Bart provides the chemical fiber mesh screen changer as the plate hydraulic mesh screen changer, which is controlled by hydraulic pressure, mainly composed of chamber, filter mesh board and hydraulic components; the plate hydraulic mesh screen changer needs to change the filter mesh because of the filter mesh clogging after working for a period of time; through the hydraulic cylinder output power, the dirty filter mesh plate is removed to filter on the plate. The network is replaced and the replaced filter is cleaned and recycled. The feeding and exhausting structure is set up with the net changer for chemical fibers, so that the material flow can be uninterrupted during the net changeover and the net changeover can be realized without stopping the machine. Bartlett provides chemical fiber network screen changer processing capacity of 300 kg to 3700 kg per hour, to meet the production needs of different chemical fiber enterprises.