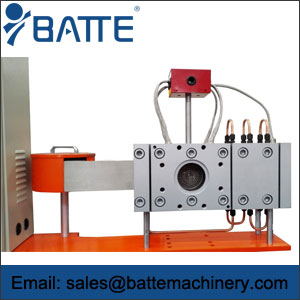

batte extrusion screen changer machine

Zhengzhou Batte (BATTE) has put forward the concept of filtration system, which refers to a set of equipment system consisting of a series of equipment units from extruder to die, mainly with filtering function, and integrating the functions of pressurization and current stabilization. It is equipped with appropriate electrical control units such as temperature, pressure and speed regulation to make it a fully automated production system.

The film melt extrusion screen changer produced by BATTE in Zhengzhou has the maximum pressure of 45Mpa, the maximum inner diameter of 500mm, no stagnation dead angle and no leakage up to now; the number of filter elements in the melt chamber can be from 1 to 48, and the extrusion screen changer area can be from 0.3m2 to 30m2; the melt pipe can be processed into various angles and specifications according to the requirements of the production site to meet the rational layout of the production line, and the inner surface smoothness can reach Ra0.0. 2, at the advanced level in China; in heating mode, there are ordinary electric tile (ceramics, cast aluminium) heating, Jacket Medium heating, infrared heating, electromagnetic heating and other ways; our company also provides various structural forms of filter core, seals and discharge exhaust valves, as well as auxiliary equipment matching with filter equipment such as calcination, cleaning, preheating and other equipment, and can be supplied separately. Customized according to customer's needs.

More about screen changer products:

Batte is a professional screen changer manufacturer, supplying screen changer, especially screen changer for extrusion mould