What are the uses and advantages of the dual column screen changer?

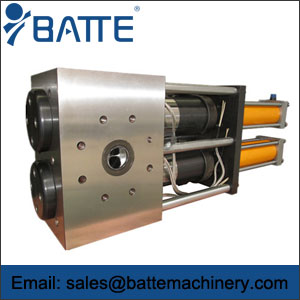

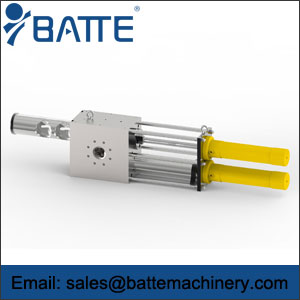

The purpose of the dual column screen changer

The dual column screen changer is particularly suitable for the melt filtration requirements of high-level automated production lines. The product is suitable for the production of products such as boards, sheets, films, pipes, wire drawing, optical fibers, cables, etc. Suitable raw materials include: PP, PE, ABS, PS, PET, PVB, PBT, TPE, PMMA, PC, PA, etc.

Advantages of dual column screen changer

1. A good sealing structure design effectively reduces the resistance of mesh changing and reduces the working pressure of the hydraulic system under high temperature and pressure conditions without material leakage or seepage.

2. It adopts an integrated structure with no load-bearing gaps, strengthening the load-bearing pressure and making the system's load-bearing pressure higher.

3. The plunger screen changer is made of high-quality alloy steel and nitrided to extend the product's service life.

4. Integral engineering oil cylinder with long service life.

5. The alternating working mode can ensure continuous and stable material flow during the screen changing process, as well as the repeatability of process parameters.

6. After rheological optimization, the honeycomb board effectively reduces fluid shear during the extrusion process.

Working principle of double column screen changer

The dual column screen changer adopts a dual column and dual flow channel design, with two filters working simultaneously. When replacing the filter screen, one screen operates and one screen is replaced, without stopping the machine to change the screen, without interrupting the material flow, and the production process is continuous and uninterrupted. It has significant advantages of high pressure and high temperature resistance, and there is no pressure fluctuation during the screen change process.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071