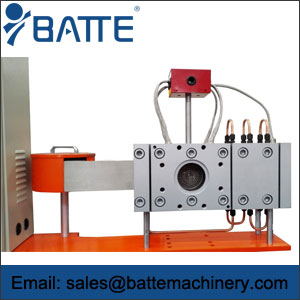

Manual Screen Changer Application, Working Principle, Advantageous Features

Manual screen changer is also called manual screen changer filter, which is suitable for all kinds of high viscosity melt extrusion line. Manual screen changer has two channels for polymer media flow on the moving slide, and the two working positions are alternately put into the working state through the manual switching device (toggle lever). It adopts unique rigid material and compensated sealing design, which can satisfy most of the polymer extrusion production, and it is easy to be installed and operated in conjunction with the extruders of different standards.

The manual screen changer is compact and occupies little space; unique rigid material, compensating seal design, high wear-resistant, high pressure-resistant, high-precision, long-lasting and durable; the operating lever is processed with texture to increase the operating experience, and the lever can be adjusted according to the site location; the positioning block and the positioning bolts ensure that the position of the screen block is accurate during the quick triggering of the trigger lever.

BATTE melt pump company can provide plate type, column type, round, oblong, arc, cylinder, single station, multi-station, shutdown screen changer, non-stop screen changer, electric heating, thermal media heating and so on many series of various specifications of the screen changer products, and at the same time, can provide the supporting melt pump, screen changer, drive valve and other integrated solutions.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

More about screen changer products:

Batte is a professional screen changer manufacturer, supplying screen changer, especially screen changer for extrusion mould