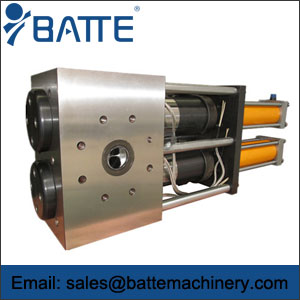

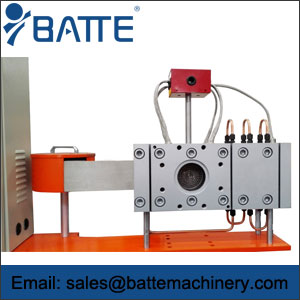

Plastic extruder screen changer machine

Most of the materials that are used to produce plastics contain impurities. These impurities can be easily removed by replacing the net on the flow path of polymer melt after the plastic extruder is simplified. The net is a textile SkyDrive with the same diameter of the plastic extruder barrel.

Usually, by several layers of different mesh with a package group. The fine net minimum solid particle filter melt stream, the outer layer of the coarse mesh is solid, can prevent premature particles larger into the inner layer of mesh.

In order to resist the force generated by melt flow, a circular steel tray with a dense hole is called a guard plate, which is embedded in the groove of the end of the extruder cylinder, and consulted.

In order to replace the blocking net, remove the downstream equipment first, replace the old net with a clean net liner and reinstall it to the production line.

screen changer

The method of replacing the net group does not need to stop work and cost labor. The machine according to its design is divided into two main types: interchangeable type and continuous type.

The interchangeable plastic screen changer has two identical groups. One of them is installed on the melt flow path. When the net group becomes dirty, replace it with another set of clean same groups. At the same time, the old same group was replaced. The two sets of net sets are mounted on the same steel plate, revolving around an axis, or slipping straight along the guide rail. The former is manually operated by a lever, and the latter slides back and forth from one side to the other by hydraulic.another net switching operation uses a valve to flow the dissolved body from the same block in the same group to the new same group.

Continuous netting screen changer: the continuous converter moves the new net into the melt and moves the old net simultaneously. The moving speed of the net change can be automatically adjusted according to the miscellaneous mass, and the continuous exchanger can eliminate the pressure and the change of the melt temperature during the intermittent operation.

A set of continuous screen changer is designed based on a rotating slider. A number of network groups are arranged around the turntable driven by the ratchet machine. Turn the turntable, move the used old same group from the melt flow, and switch to a new group by hand before touching the melt flow.